DSP Comparsion – Configuring a 3-Way Loudspeaker (Part 3)

DSP Comparsion – Configuring a 3-Way Loudspeaker. Pat Brown looks at the transfer function of the DSP to a loudspeaker .

The last two issues of the Syn-Aud-Con Newsletter included Parts 1 and 2 of “DSP Comparison.” The response was significant so the articles seem to have struck a chord with our readers. I normally avoid articles that compare products from various manufacturers because they never tell the whole story, and someone always gets left out. “DSP Comparison” was no exception and my apologies to anyone who feels slighted.

A Recap

Part 1 showed that the differences between DSPs can be significant if the settings are simple numerical entries as specified by the manufacturer. Part 2 showed how that careful attention to setup can produce nearly identical transfer functions between units.

In this third and final installment, I elected to take a different path. This time I will look at applying the transfer function of the DSP to a loudspeaker.

Conventions

In this article a passive loudspeaker is one which connects directly to an amplifier with no additional processing required. An active loudspeaker is one which connects directly to an amplifier but requires line level signal processing prior to the power amplifier. A powered loudspeaker is one whose amplifiers and signal processing are internal and only a line level drive signal is required for operation. A loudspeaker system refers to the combination of the individual loudspeaker elements, i.e. the low, mid and high frequency transducers as well as any supporting electronics. In addition, LF refers to low frequency, MF to mid frequency and HF to high frequency.

This article will focus on the second type – active loudspeakers that utilize external signal processing to achieve their target response. This is the most widely used configuration in the marketplace for high-level playback systems. The configuration process will produce a system that could be re-engineered and sold as a powered loudspeaker.

We will assume that any DSP can produce the required drive functions if care is taken in configuring the settings.

Configuration

The loudspeaker selected as an example is a 3-way system configured for triamp operation – an active system. Each loudspeaker in the system spans approximately one decade in frequency (a 10-to-1 frequency ratio). The DSP settings were supplied by the manufacturer, and one of the DSPs from Part 2 was used to produce the drive functions (Figure 1). The loudspeaker was tested at 8 meters in such a way as to produce a meaningful sensitivity specification, which traditionally referenced to a 1 meter distance and a 1 watt input to the loudspeaker. Previous articles have shown the difficulty in referencing the sensitivity (and other sound levels) to the applied power. All such specifications must ultimately specify the applied RMS voltage to the loudspeaker, the most common being the application of 2.83Vrms to the loudspeaker’s terminals. This is the voltage that would produce 1 watt into an 8 ohm resistive load. Of course the loudspeaker is not an 8 ohm resistor, so we are not actually driving it with one watt. This is actually a voltage specification that is expressed as a power specification with some assumptions, as are essentially all loudspeaker power ratings.

.

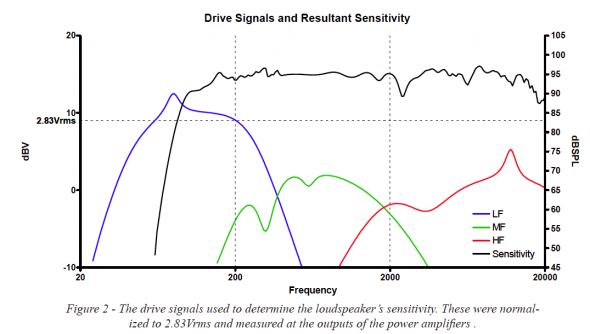

DSP Settings

The manufacturer-supplied DSP settings are typical of what might be required for any active 3-way system. They were presented in the form of a spreadsheet and entered manually into the DSP. A high resolution axial impulse response was gathered to verify that the DSP settings produced the desired response (Figure 2). The DSP blocks include high-pass and low-pass filters (to produce a crossover network), parametric equalization, a signal delay and a polarity reversal. The DSP was set at unity so that one volt input produced one volt output. The low-frequency output was used as the reference for the unity setting. Both mid and high frequency outputs were attenuated relative to the low frequency output as per the manufacturer’s settings. The use of the low frequency channel as the reference emulates the crossover networks used in passive loudspeakers where the high frequency element is resistively attenuated to match the sensitivity of the low frequency element to produce a flat broad band response.

Note that all three channels of the DSP could have been set at unity, and the level balancing between the LF, MF, and HF done with the power amplifier input sensitivity controls. One can make convincing arguments for either method, but in this case the manufacturer clearly specified the required mid and high frequency attenuation so it makes sense to implement it at the DSP. Another reason is that the relative levels have a significant effect on the response at the crossover frequencies. The crossover topologies are rather complex and the manufacturer invested significant effort into their determination and specification. A side benefit is that once these levels are set all three outputs of the DSP can be linked via software and the loudspeaker’s overall level adjusted with a single software control (i.e. the output gain of the DSP).

The end result is an active loudspeaker that emulates a powered loudspeaker, even though the signal processing, amplification and loudspeaker elements are external rather than housed in the same enclosure.

Measured Data

Figure 2 shows the drive signals as measured at the output of the power amplifiers. The low frequency amplifier was adjusted to produce +9dBV (2.83Vrms) at its output. The signal processing was bypassed when establishing this reference voltage. Note that when the signal processing is engaged, the reference to 2.83Vrms becomes frequency-dependent and somewhat ambiguous. Since the LF response requires shelving boost and band pass filters (as per the manufacturer), the output voltage is in excess of 2.83Vrms for the very low frequency part of the spectrum. Since the MF and HF responses are attenuated to level match the LF component, the drive signals are well under 2.83Vrms for most of the bandpass of the loudspeaker. Only one frequency of the entire spectrum is actually 2.83Vrms (approximately 200Hz) which is indicated in the figure. The resultant sensitivity is to serve as a level reference that will be scaled by the system designer to produce the target SPL. Great care should be taken in comparing sensitivities between different brands of loudspeakers, especially active ones as they may not have been measured using the same methods. As I have stated many times, specifications should not be used to make comparisons between brands, only to determine the suitability of a product for a specific application. This is engineering data, not marketing data and unless the data were collected under the exact same conditions it is not comparable.

This also illustrates a caveat of sensitivity specifications in general. We can see that the application of 2.83Vrms is a generalization. It’s even more problematic to express this as an applied power in watts. Each loudspeaker has a dramatically different impedance, and none of them are 8 ohm resistors. The drive voltages vary over a range of 10dB. There is just no way that we can say that we are applying one watt to this loudspeaker, and any attempt to actually make it one watt by modifying the drive voltage would result in a very undesirable response from the loudspeaker. In spite of all of this, the specification is commonly referred to as the “1W/1m” sensitivity.

System Sensitivity

All of this serves to show some of the caveats regarding sensitivity ratings. A distinction must be made between the sensitivity of a loudspeaker system and the individual components. The mid and high frequency elements in this example have much higher sensitivities than the system as a whole. They must be “de-sensitized” to produce a flat frequency response. It would be easy for a “one number” sensitivity specification to miss this, since the manufacturer could have used the highest figure of any of the individual elements. If the loudspeaker system is broken down into sub-systems, then the sensitivity would need to be modified accordingly. The loudspeaker featured in this article can also be purchased as a separate mid/high frequency element and combined with a separate low frequency element(s) to produce the same response. In this case the mid/high frequency element must be tested as a loudspeaker system and the resultant sensitivity will be significantly higher than that shown here for the entire system (Figure 3). Casual comparisons of “one number” specifications can easily overlook these caveats.

Other Loudspeaker Types

The sensitivity test for an active loudspeaker is much more involved than that for a passive loudspeaker or even a powered loudspeaker. Passive and powered loudspeakers have all of their required processing on board, so we simply need to present a broadband sweep at a fixed voltage to the loudspeaker. The sweep can be log or linear, since the transfer function (change to the signal) is being measured. I use a log sweep for increased low frequency noise immunity. The sweep voltage should be 2.83Vrms for passive loudspeakers, and 1Vrms is convenient for powered loudspeakers with line level inputs.

The Whole Picture

Figure 1 shows the driving signals plotted on the same graph as the resultant sensitivity. This is a very meaningful display, as it shows the response that results from the applied signals, normalized to a one meter distance. A sound system designer can (and should) start with this response when performing level calculations for a design. Figure 4 shows the maximum continuous Vrms that can be applied to the system before it becomes non-linear. This voltage was arrived at using the abbreviated power test described in the article “Loudspeaker Toaster” in this issue. Since we have a reference sensitivity at a known level (2.83Vrms or +9dBV) and a known Vrms at which the loudspeaker becomes non-linear due to heat (42Vrms or +32dBV across the woofer), then a gain figure above the reference sensitivity can be determined. In this case the gain would be 32dBV – 9dBV or about 23dB. This is a useful number for a sound system designer to know as it allows them to quickly and accurately determine the maximum SPL that the system can safely produce. Alternately it can be used to find the maximum working distance from the loudspeaker at which the reference sensitivity can be achieved. Combining the reference sensitivity and the maximum Vrms indicates that 119dBSPL can be expected at 1 meter from the loudspeaker system under free-field conditions. Extrapolated to 30m, the level would be approximately 90dBSPL. This is direct field only, and indoors a room gain of 6-10dB can be expected.

Amplifiers must be selected to drive the loudspeaker. If we do so according to the require voltage characteristic of the program source, then a 440W@8ohm sine wave rated amplifier can be expected to reliably produce 90dBSPL at 30 meters indoors. This is about the maximum SPL that an audience should be exposed to from a sound reinforcement system. This is the amplifier size for the LF. The MF and HF elements do not need as much voltage swing and they can be drated by approximately 10dB as per Figure 1. However, I would suggest using the same amplifier size as for the LF and taking the extra range as additional peak room.

The Equivalent Amplifier Size

Using the measured voltage sensitivity as a reference, it can be see that approximately 23dB of gain can be expected above the reference sensitivity of the loudspeaker. The CLF gives an Equivalent Amplifier Size of 440W, which means that this system can be continuously driven by an amplifier with this 8 ohm power rating using IEC 268-1 spectrum pink noise for at least five minutes before it becomes non-linear. If the same sized amplifier were used with typical broadband audio program material (i.e.music from compact disc) with only occasional clipping, it is unlikely that any permanent damage to the loudspeaker would ensue and that the maximum safe SPL of the system (regarding the loudspeaker) is being realized. So, the Equivalent Amplifier Size can then be seen as a maximum appropriate amplifier size for typical use. A larger amplifier can be used to provide additional room for peaks, with 3dB increments being meaningful (and expensive!). Note that whatever the amplifier size, the maximum Vrms must not be exceeded. While this test is for thermal failure, excess excursion can occur if the amplifier is too large. Tom Garson describes additional failure modes in the side bar below.

Reality and Conclusion

The complete setup of an active loudspeaker system beginning with the DSP has been given. This produced a sensitivity rating which was scaled to the maximum Vrms, and extrapolated to a remote listener position. This information should prove useful to anyone designing, installing or operating sound systems. pb

How Can I Break Thee? Let Me Count the Ways… by Tom Garson

Over the last 25 years or so, we’ve been a factory service center for JBL, EV, Altec, Gauss, Celestion, etc. All of these companies make, or made, good products, and some are/were superior in nearly all respects. Every now and then, somebody or some machine would screw up and build a defective loudspeaker. Occasionally one of those escaped the factory in some form of product. That’s what warranties are for.

In addition to thermal failure (burnt voice coil) you can sometimes tell if a speaker has been over driven repeatedly by examining the physical condition of the cone and voice coil structure.

Cones that were not intended for use in a high output woofer are usually thinner and lighter. These cones will show flower petal shaped creases in the paper, caused by bell mode resonance when driven too hard with frequencies below their design range. Even thick reinforced woofer cones can demonstrate this over a long enough duration of heavy usage.

A cone can collapse near the glue joint that connects it to the voice coil from excess driving force, resulting in softening of the paper or even circumferential creases. This is often the cause of coil lead failure because many speakers bury the lead in the coil-form-to-cone glue joint. Many high output woofers now bring the coil leads up the inside of the coil former and curve them through the air to the cone, bypassing the cone/coil junction area. JBL’s dual-coil neodymium woofers bring flexible lead wires back through the center of the magnet structure directly from the coil former, bypassing the cone connection entirely. I think this is the best approach.

The coil form can collapse accordion style near its junction with the cone, causing the lead wire to break. This will usually also cause the voice coil to misaligned in the gap, rub on the pole pieces and then short out. This is often mistakenly thought to be the result of the coil failure, rather than the cause.

Over excursion can deform the bottom of the voice coil in some speakers, due to its hitting the back pole piece. This can also precipitate coil former deformation at its connection to the cone. See above.

The tinsel lead wire can fail open, especially if it is too short or of less than the best quality. It is good policy to always check for continuity between the points where the tinsel leads connect to the cone before initiating an irreversible postmortem.

Flat wire wound coils will sometimes break at the fold that is made where the wire at the coil ends is directed up the voice coil towards the cone. Sometimes the coil builder will put a bit too much of a crimp at that point, causing a crease which will be a point of weakness.

Some manufacturers actually weld or solder (usually silver) a highly flexible lead wire to the more rigid voice coil wire, due to the differing mechanical requirements for the different functions of the wire. This connection is a weak point if not done exactly right. When bad it can still look perfect to the naked eye. Most compression drivers use this technique. All reputable manufacturers of drivers consider this to be a warrantable failure, even if it usually only shows up under the stress of higher power operation.

Speaker components are very creative when it comes to finding ways to break. JBLs service binder has multiple pages of QA codes, each of which describes a specific failure mode of a transducer. tg