Inside Amplifier Power Ratings – Part 3

by Pat Brown

Amplifier Power Ratings – Part 3, Pat Brown will convert some utility power into audio power.

Real Testing – Matching Amplifier Data and Specifications

I’ve done enough theorizing and musing about power and power ratings in parts 1 and 2 of this series (July, August 2011). Let’s convert some utility power into audio power. First, some details about the testing.

The Source, The Load

“Source” and “load” are usually associated with amplifier and loudspeaker. To perform the testing I had to zoom out another level and consider the AC source to the amplifier (these amplifiers need a lot of juice). The amplifier has to get its power from somewhere, whether it be the utility power company, a generator or a large array of hamsters on treadmills.

I added a new power circuit to the lab for the testing. The line voltage can be 120 volts RMS or 240 volts RMS. The circuit breaker is 30 amps. The electrical panel for the lab is near the amplifier rack, so line losses are small and tripped breakers can be easily reset. The reason for all of the fuss is that when you are attempting to draw power that is at the limits of what can be safely sourced from the utility company, details that one might normally take for granted suddenly matter. The amplifiers need a hardy power source. Remember that when you design your power distro.

So now all I have to do is plug-in the amplifier, right? At these higher current ratings, there are several choices of power cord plugs for both the electrical outlet and the amplifier inlet. For the outlet, I chose a versatile, 4-conductor connector that can be easily wired for the voltage and grounding scheme needed. The amplifier inlet connector was different for all three amplifiers tested. After a trip to Home Depot, and some rummaging through the parts bin, I was able to fabricate a power cord for each.

The audio power must flow to something. The loudspeaker is the obvious candidate, but they get really loud at these drive levels and are expensive to replace. I mentioned a somewhat crude dummy load in Part 1, but it had some shortcomings. As before, when you’re pushing the envelope, the details matter. I decided to build a new load.

Figure 1 shows “The Mother- Load,” a 4-channel by 8-ohm dummy load. There are four 1,800-watt water heater elements (purely resistive) that are mounted into a 25-gallon steel tank filled with environmentally-friendly (and non-flammable) mineral oil. All of the tests in the article were performed driving the Mother- Load. Yes, I know the name is sexist, but “Father-Load” just doesn’t feel right.

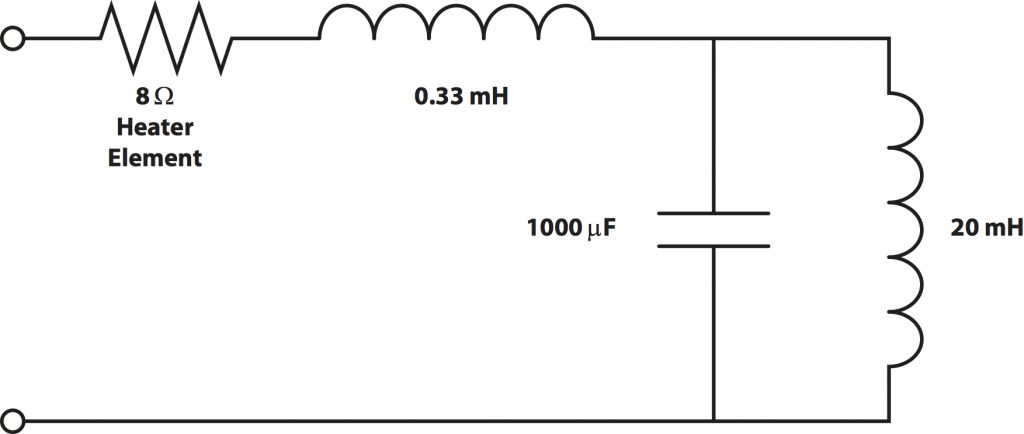

A feature of the Mother-Load is switchable reactive circuits that can be added to each 8-ohm element. I lifted the schematic from the Rane Professional Audio Reference. It is shown in Figure 2.

Figure 3 shows the overlaid impedances of the Mother-Load configured at 4 ohms with and without the reactive circuit. I have also included the impedance curve of a real-world 4-ohm load to demonstrate that the average impedance of a typical loudspeaker is higher than its rated value.

Why do I (perhaps) bore you with these details about power circuits and loads? Because they matter. If someone lays out a bunch of cash for an amplifier that they expect to provide thousands of watts of power, they had better think about where the power is coming from and where it is going.

If you can’t source or dissipate the power, save some money and buy a smaller amplifier. The voltage and current from these amplifiers will challenge the Mother-Load. What about a “mere mortal” loudspeaker voice coil?

The Test Signals

The power from an amplifier is completely waveform-dependent. I tested these amplifiers using three signal types. Here are the signals and a few relevant attributes:

1) Continuous Sine Waves – simple, unambiguous, and worst case with regard to current draw and power dissipation. Easy to generate, easy to measure. I mentioned my affinity for power ratings based on continuous sine waves in Part 1.

2) Pink Noise – more “real-world.” The crest factor and bandwidth are more “music-like,” yet there is still enough stability to allow a “one number” rating to be estimated from an analog meter or bar graph.

3) Tone Burst – Music contains transient events that can have very high amplitude and very short duration. I used don Keele’s Peak Tone-burst test for this purpose. The spectral content and duty cycle can be sculpted to emulate a kick drum, staccato bass guitar, or whatever, but in a way that is completely repeatable and measurable.

I used Don’s Tri-Tone Burst generator, a program that runs under Igor, to produce the tone bursts. A center frequency of 80 hz was selected to emulate the spectral content of a kick drum. The tone burst includes 6.5 cycles of three sine waves spaced at 1/3-octave and centered at this frequency.

The Amplifiers

I selected three amplifiers to test. They all claim output power in excess of 1 kW, but there are significant differences between them in terms of ratings, features and price. The measured data is mainly useful for seeing how each performs under various signal types and load conditions. Here is a little background on each.

The first is a QSC PL380 that I use for loudspeaker power testing on a regular basis (typically in bridged-mono). It is analog by design. DSP processing and control is available, but I don’t have the required module, etc.

The second is a Crown I-Tech 9000 HD that I use in SynAudCon training classes. It has extensive on-board DSP and I monitored its performance with the company’s System Architect software.

The third is a Lab.Gruppen PLM 20000Q that is on loan for evaluation. I used two of the four channels, since the other amplifiers are 2-channels.

While these models are apples, oranges and pears, they are all multi- kilowatt rated amplifiers and are at or near the top of the product line for each manufacturer.

Amplifiers can have many power ratings, based on load impedance, number of channels driven, signal type, etc. Most manufacturers provide a ratings matrix for a sine wave signal. See Figure 4 for an example (click to enlarge)(courtesy Crown International).

It gets even more complicated when you perform the testing for multiple signal types and for both resistive and reactive loads. Since this is an article, not a book, I have only presented some of the results in the data matrix (Figure 5).

I monitored the current from the electrical circuit during the testing. The 30 amp breaker didn’t trip until about 40 amps. I should again emphasize that these amplifiers need a lot of utility power, along with special cabling and connectors to produce their rated sine wave wattages at 4 ohms.

I tested each amplifier’s open circuit output voltage as the first test. This basically means “disconnect the load and see what the amplifier’s output voltage is looking at air.” This is a useful reference for considering what happens under load.

Sine Wave Performance

None of the amplifiers had any problem maintaining their open circuit sine wave voltage into a 8-ohm load, even with two channels driven. All of them could produce their open-circuit voltage into 4 ohms, but fans were on “high.” Amplifier ventilation would be a definite issue for 4-ohm loads and low crest factor signals.

Pink Noise and Metering Issues

Pink noise is the most real-world of the test signals. It’s also the most difficult to measure accurately and refine to a single number. Sine wave clipping is trivially easy to observe on an oscilloscope. Pink noise clipping has to be pretty severe to see on a scope, so I had to rely on the on-board metering of each amplifier. That’s where things become gray. Consider the following:

- 1) Is clipping even possible? Most modern amplifiers have algorithms that prevent clipping. How fast does it kick in? How much “over” does the amplitude have to be before clipping suppression activates?

- 2) How often does the clip light have to flash before I declare that I have reached clipping? Once? Fairly often? Continuous illumination? There is some interpretation required here.

- 3) Once I have decided that I’ve reached clipping, what is the measured voltage? Even with an expensive True- RMS voltmeter with both digital read-out and a bar graph, it is a judgment call to assign a single number to something that has a 12 dB difference between its peak and RMS value. It’s another judgment call.

The clipping indicators of three different brands are bound to use different criteria for each of these. And no, you can’t detect the onset of clipping by listening only. In part 1, I showed how the peak program meter (PPM) is designed to ignore clipping that is likely inaudible (6-8 dB). For these and other reasons, I wouldn’t use the pink noise voltage and power ratings for comparing various brands of amplifiers. Discrepancies of 3 dB or more could be expected, and in this power range that could be hundreds of watts.

As proof that all of this matters, just look at the open circuit voltage comparison between the sine wave and pink noise for each amplifier. The sine wave has a 3 dB crest factor and the pink noise a 12 dB crest factor. That’s a 9 dB differential.

Yet when I calculate the dB difference between sine and noise output for each amplifier, I only get the expected 9 dB for the QSC. That tells me that there is a difference in the metering of the three amplifiers. If you look at the ratings matrix it appears that the QSC output voltage and power is significantly lower than the other two with pink noise, but this is obviously due at least in part to differences in metering. I could have easily produced a higher voltage from the QSC using a different visual criteria for clip. That’s why I hate “one number” ratings when taken at face value.

Things Amplifiers Hate

There are two conditions that none of these amplifiers like – low crest factor signals and 2-ohm loads. The continuous sine wave testing was by far the most revealing with regard to how much power the amplifier (and the electrical outlet) could source. I had to reset the circuit breaker numerous times during the sine wave testing into lower impedances with two channels driven.

I should mention that all of the amplifiers recovered nicely from circuit breaker trips. Once they powered back up they resumed working, and the PC-controlled models re-established communications. All of the amplifiers have internal breakers, and none of them tripped during any of the tests.

None of these amplifiers could maintain their output voltage into 2 ohms with a sine wave source. The results varied so dramatically that I removed that data from the matrix. They “sort of” work at 2 ohms with pink noise, although I believe that the voltage limitations were due more to the amplifier’s “smarts” than due to their electrical current limitations. The designers are trying to protect their amplifier and your loudspeaker. They are trying to keep you from “running with scissors” when you insist on overloading your amplifier to “get more watts.”

None of the amplifiers cared if the load was resistive or reactive. That is a very good thing for a commercial power amplifier, and something that hi-fi amplifiers often have a problem with.

Burst Testing Results

These amplifiers get their largest power ratings from tone burst testing. Ironically, that was the easiest signal for all of the amplifiers to pass. none of them had a problem producing their maximum voltage for a few tens of milliseconds, even into 2 ohms with both channels driven.

I did trip the circuit breaker a few times at 2 ohms, so this test was really more about the utility power source than it was the amplifier. It’s a shame that this number wields so much influence in the marketplace.

The Truth About 2-ohm Loads

If you want the maximum output voltage and most linear performance from your amplifier, don’t load it to 2 ohms. I believed this before doing these tests, and I believe it even more now. You can see how each amplifier’s voltage sags under different loads in the matrix. Voltage sag is bad. I would bet money that anyone who is conducting amplifier shoot-outs for driving their 2-ohm monster sub is mainly listening to each amplifier’s protection circuitry. If you want fidelity, design your subs to be 4 ohms or higher (that’s RATED impedance – the actual impedance will be higher yet) and buy more amplifiers.

An Important Test That I Omitted

While the data matrix is useful for assessing the performance of each amplifier, it is not the whole story. If you change the program material to music, and drive both channels into 4 ohms or less, there will likely be significant differences in the sound, due at least in part to the philosophical underpinnings of the operation of the protection algorithms.

The best way to assess the amplifier’s performance under these conditions may be the FTLC6P test. It requires some Favorite Tunes, a Lawn Chair, and a 6-Pack of your favorite beverage. While the results are subjective, they may the be most revealing test of all for comparing overloaded amplifiers.

The Inevitable Comparisons

While I have stated that this was not an amplifier shoot-out, people will inevitably make comparisons. That is why I suggested the dBW scale in part 1, as opposed to “watts” and have included it in the matrix for the sine wave ratings.

Differences of less than 1 dB are negligible. A 3 dB difference may be audible under controlled conditions. The largest dB differences were for pink noise, which I showed above to be the most difficult signal to characterize with a single number. When we are looking at amplifiers rated at over 1 kW, the relative differences will be small.

Conclusion

The testing validated some important points from parts 1 and 2. here’s a quick summary:

- 1) A 1 khz sine wave rating into 8 ohms is the best measure of an amplifier’s performance for a sound system designer. The amplifier acts as a constant voltage source into 8 ohms. The voltage can be scaled to any crest factor by calculation. This makes accurate sound pressure level calculations at the drawing board possible.

- 2) Don’t load your amplifiers to 2 ohms to “get more watts.” When the voltage sags, you are losing output level and engaging protection algorithms.

- 3) Amplifiers don’t like low crest factor signals. If you excessively compress or limit the program material, and drive the amplifier to clipping, you are likely engaging the amplifier’s protection algorithms, with significantly audible ramifications.

- 4) Don’t compare amplifiers using power ratings derived from burst testing. These are vanity specs that look impressive but reveal very little about the amplifier’s performance.

- 5) Summing the instantaneous power ratings of all channels and thinking that you can get that much “power” is fantasy. Doing so is misleading at best and it promotes erroneous thinking and bad behavior in the marketplace. It’s putting a modern face on the peak power rating wars of the 1970s.

I was truly impressed in different ways by each amplifier that I tested. The output capability and efficiency given their size and weight is a true miracle of modern technology. It’s my hope that this series of articles sheds some light on how modern amplifiers operate and how their specifications are determined. This should lead to better correlation between the predicted and actual performance of each in real-world sound systems. pb